Research and Development

Our interests are in research and development of sustainable processes for the manufacture of complex organic chemicals using catalytic processes.

Using the iPRD Process Lab we can evaluate their scale-up using batch or novel flow techniques and a variety of analytical methods.

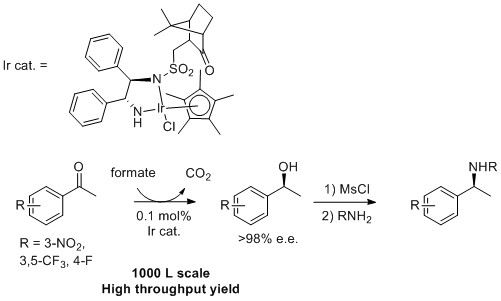

Catalytic Hydrogen Transfer Processes

Catalytic asymmetric ketone and imine/iminium reduction. We are building on work carried out in industry that resulted in numerous scaled-up production processes. Current focus is on better catalysts and continuous flow processing.

Enantioselective iridium-catalysed transfer hydrogenation of acetophenone to benzyl alcohol followed by amination to form benzylamine.

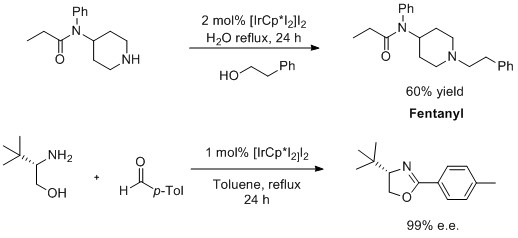

Catalytic dehydrogenation of alcohols is now well established, less so that of amines. We are investigating in-situ formation and reaction of imines with different nucleophiles.

Hydrogen borrowing, redox neutral reactions are receiving much interest. We are looking at functional group interchange to make heterocycles as well as N-alkylation and dealkylation reactions.

1. Iridium catalysed alkylation of secondary amine to form fentanyl. 2. Iridium-catalysed cyclisation to form substituted oxazoline.

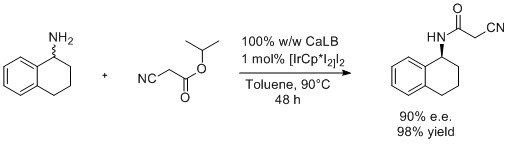

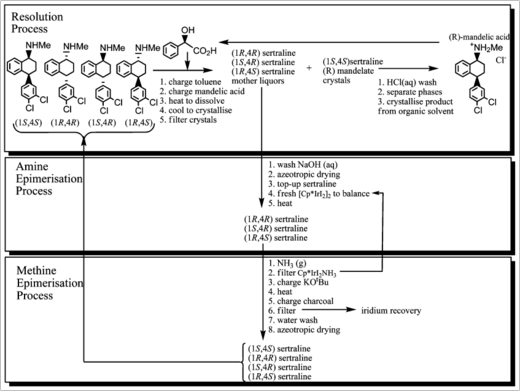

Dynamic Kinetic Resolution of Amines

Dynamic kinetic resolution of amines. Our previous work has shown successful DKR’s with primary and some secondary amines using hydrogen transfer catalysts for racemisation. An interesting class of substrates we are evaluating, with some initial success, are aziridines.

Dynamic kinetic resolution of racemic primary amine using CaLB and iridium catalysts to form one enantiomer of the chiral amine in 90% e.e.

Crystallization Induced Asymmetric or Diastereomeric Transformation (CIAT / CIDT). This work builds on our earlier findings that the mother liquors from diastereomeric crystallisations can be racemised and recycled resulting in higher yielding and less wasteful processes.Current research is looking at simultaneous crystallisation and racemisation of alcohols and amines that form conglomerate or diastereomeric crystals.

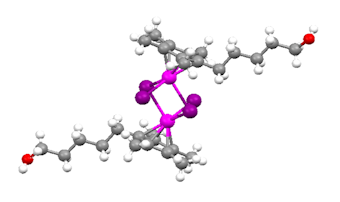

The immobilisation of hydrogen transfer catalysts would enable not only their separation from product but facilitate their recycle or use in continuous flow processes.Our approach is tethering via the stable eta-5 Cp* ligand, which avoids metal leaching but also allows use of ancillary ligands for flexible use in different types of hydrogen transfer reactions. R&D is currently being done through a TSB supported project involving University of Cambridge as well as AstraZeneca, Pfizer and YPT.

Mechanistic work is essential in underpinning many of these processes to help improve catalyst activity, improve yields and ensure consistent processes. We are looking at aspects of this at the moment.

Processes to Make Sustainable Chemical Feedstocks

- Catalytic transformation of lignin derived polyphenolics. A project is underway looking at phenolic deoxygenation.

- Catalytic transformations bio-derived alcohols and acids such as sugars, hydroxy acids. Summer student and industry projects are looking at these types of reactions.